- Definition of a motion transformer

- Motion transformer types

- Focus: Rack & Pinion

- Focus: Crank & Rod system

- Quiz

- Glossary

Overview of motion transformer types

The following section introduces some examples of mechanical transformers and highlight their advantages and disadvantages.

Screw & Nut

The screw and nut system allow to transform a rotational movement into a translational movement by combining the movements of a screw and a nut.

Screw and Nut

Source: https://quizizz.com/admin/quiz/5f17c374c1a99b001b506a90/bolt-nut-assessment

Advantages: This mechanism allows to exert important forces and pressures. It also allows for fine adjustments.

Disadvantages: This mechanism generates a lot of friction.

Its fragility can lead to guiding problems.

The system is slow unless it has a large screw pitch. Example: Jack, vice-grip…

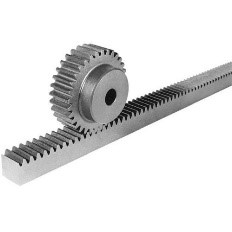

Rack & Pinion

The rack and pinion system transforms the rotational movement of the pinion into a translational movement of the rack or vice versa.

Rack and Pinion

Source: https://www.indiamart.com/supertekengineers/industrial-gears.html

Advantages: There is no slippage during the transformation of this movement. The strength of this system is relatively high.

Disadvantages: The gears that are used may require extensive lubrication as there is a lot of wear.

This mechanism requires precise adjustment because of the teeth between the wheel and the rack.

It is not a cyclic movement; it is a finite movement (you must stop when you reach the end of the rack).

Use cases: Car steering, net tensioners (badminton net for example), adjustment mechanisms of some microscopes, camera tripods, etc.

Crank & Rod system

The crank and connecting rod system transforms rotary motion into reciprocating motion (straight back and forth) and vice versa.

Crank and Rod system

Source: https://technologystudent.com/cams/crkslid1.htm

Advantages: This mechanism can operate at high speed.

Disadvantages: There is a lot of friction due to the many joints in this system. This requires a lot of lubrication.

Use cases: Petrol engines, diesel engines, pumps, medical respirators, steam locomotives, old sewing machines, spinning wheels, grinding wheels, etc.

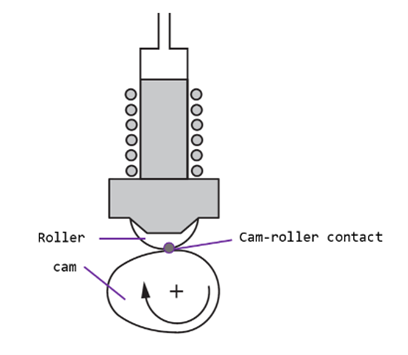

Cam & Roller System

The cam and roller system (also known as the cam and push rod system or guided rod) transforms the rotational movement of the cam into a reciprocating movement of the push rod.

Diagram Cam and Roller System

Source: https://www.tribonet.org/news/testing-of-cam-roller-follower-systems/

Advantages: The cam can be configured to vary the movement of the rod from one translational motion to another.

There is no slippage, the speed ratio is constant.

This system allows a considerable reduction in speed.

Disadvantages: The rod must be guided in translation.

A return spring is usually required to allow the rod to rest continuously on the cam.

There is a risk of severe vibration if the cam rotates at high speed.

Use cases: Mechanical toys, mechanisms for controlling the opening and closing of valves in a car engine (camshafts and valves), sewing machines, etc.

Comparison of motion transformer types

| Advantages | Disadvantages | Characteristics | |

|---|---|---|---|

| Screw & Nut | -Allows important forces and pressures -Used for fine adjustments | -Generate friction -Can lead to guiding problems | Efficiency: ++ Speed: ++ Stability: +++ |

| Rack & Pinion | -No slippage -High strength | -Required fine adjustment -Finite movement | Efficiency:+++ Speed: ++ Stability: ++ |

| Crank & Rod system | -Operation well on high speed | -Poor efficiency (due to friction) | Efficiency: + Speed: +++ Stability: +++ |

| Cam and Roller System | -Constant speed ratio -Can lower the system’s speed | -Rod has to be guided -Risk of vibration at high speed | Efficiency:+++ Speed: + Stability: + |